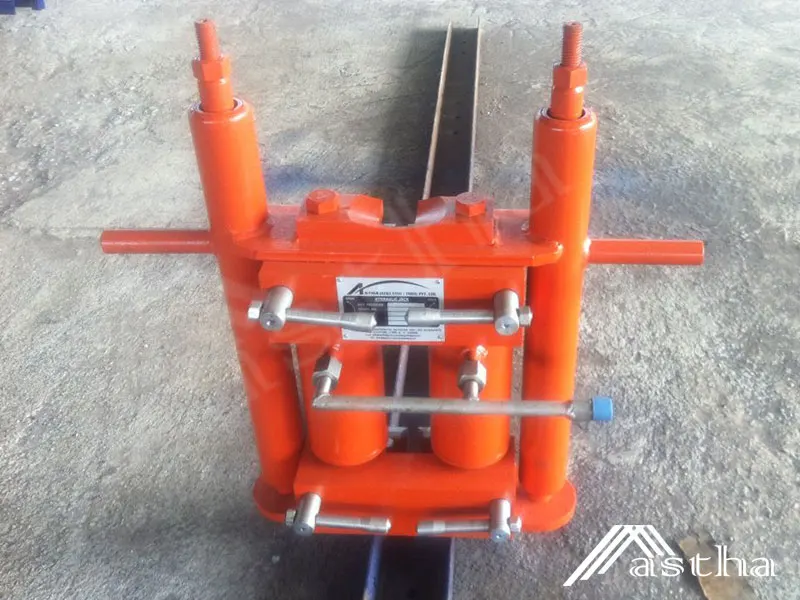

Astha Infra Engg (I) Pvt. Ltd. is the pioneer and the oldest leading supplier of hydraulic jacking systems/equipment for tank erection since 2002. Our manufacturing plant is in India. Each machine is quality-checked, performance-tested, and carefully packed. We believe in first-class customer service and are committed to building lifelong customer relationships. More than 3000 tanks have been erected using our Hydraulic Jacking Systems/Equipment in the following industries: oil refineries, petrochemical plants, fertilizer plants, power generating stations, petroleum product installations & depots, and bulk liquid storage terminals at ports. The largest diameter tank erected using our jacking equipment was a 92-meter diameter tank, and the heaviest tank weighed 1900 tons.

Astha Infra Engineering (I) Private Limited provides after-sales and after-rent services for Industrial screw jacks, either hydraulic or mechanical, which are essential tools for industrial processes. With these types of jacks, heavy machines, heavy tanks, and other heavy equipment in any industrial setting are raised by an industrial operator. After constant utilization, some jacks may require servicing, repair, or replacement for key parts to ensure performance.

We specialize in after-sales and after-rent services to industries globally in Europe, the UK, Latin America, the USA, Southeast Asia, East & West Africa, and the Middle East in our organization with hydraulic jacks and mechanical screw jacks. Our primary rental services are to clients mainly throughout India. The availability of operators in pan-India and globally would ensure an uninterrupted time cycle during the repair/maintenance.

EN

EN FR

FR IT

IT DE

DE